Reborn with Savior:

Transforming the Traces of the Past into the Future

In the heart of a bustling city, where the remnants of yesterday’s consumption accumulate more each day, Creavit envisioned a different future with its innovative approach. In this future, waste is not merely waste, but a resource awaiting transformation.

With our Savior Washbasin, created from recycled ceramic waste, Creavit opens the doors to a new and unique world for its users. Composed entirely of recycled waste, Savior’s additive-free structure causes each product to have a different color tone. In this way, Savior creates a unique aesthetic, completing the recycling process fully and flawlessly, marking a first in this field.

100% Nature

The visual language we aimed to emphasize in this innovative product was to convey the two potential disasters that could arise from the unconscious waste of water: drought and the scarcity of water that drought creates.

In the design phase of the product, we used lines that drew attention to drought to highlight the need for water conservation, while also considering the impact on all natural resources.

The SV040 has an elegant design inspired by the traces of desert winds on the sand. This modern style reminds us with every use that water waste will lead to drought and thirst in the future. With a diameter of 40 cm and a height of 90 mm, the SV040 stands out with both its ideology and ergonomics. It is made of 100% recycled materials.

The SV041 symbolizes the commitment to nature with its asymmetrical leaf patterns. This model, with dimensions of 40x33 cm and a width of 85 mm, emphasizes the need to prevent water waste. It is also made of100% recycled materials.

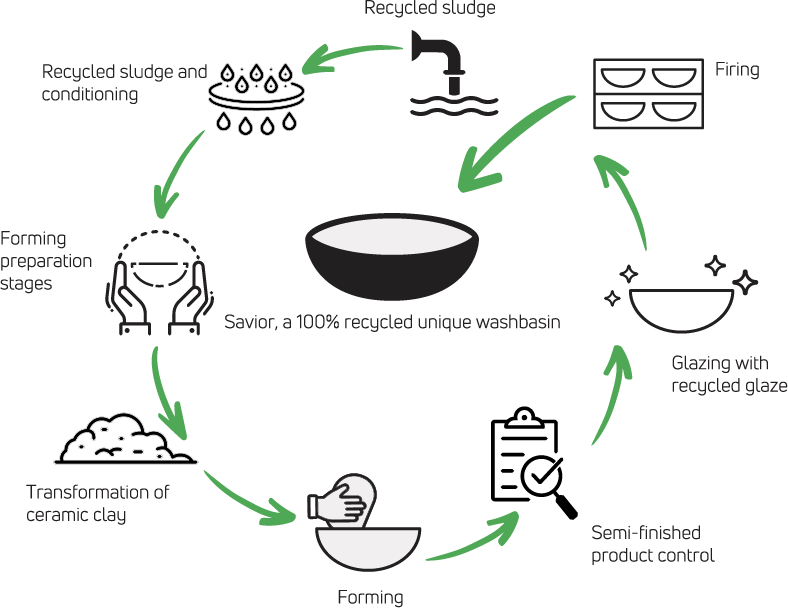

1. Recycling Sludge

Waste ceramic sludge is collected as a recyclable material and processed. This sludge serves as the raw material for sustainable sink production.

2. Recycling Sludge and Conditioning

The collected sludge is made reusable through various chemical and physical processes. This step enhances the homogeneity and quality of the raw material.

3. Forming Preparation Stages

The conditioned sludge is prepared for shaping and brought to the right density. This step helps create the basic structure of the sink.

4. Transformation of Ceramic Clay

The sludge is transformed into ceramic material, used to form the base structure of the sink. This transformation is crucial for the product’s durability.

5. Forming

The ceramic sludge is poured into a sink mold for shaping. The molding process determines the final dimensions and shape of the product.

6. Semi-finished Product Control

After shaping, semi-finished products are inspected to ensure they meet quality standards. Defective products are eliminated at this stage.

7. Glazing with Recycled Glaze

Products are coated with recycled glaze, enhancing surface durability. The glazing process completes the aesthetic and functional characteristics of the sink.

8. Firing

The glazed products are fired at high temperatures to harden them. Firing ensures the sink’s durability and long-lasting use.

9. Savior 100% Recycled Unique Washbasin

As a result of all these steps, a 100% recycled, unique sink is produced. Savior symbolizes sustainable manufacturing and an eco-friendly approach.