-

1963

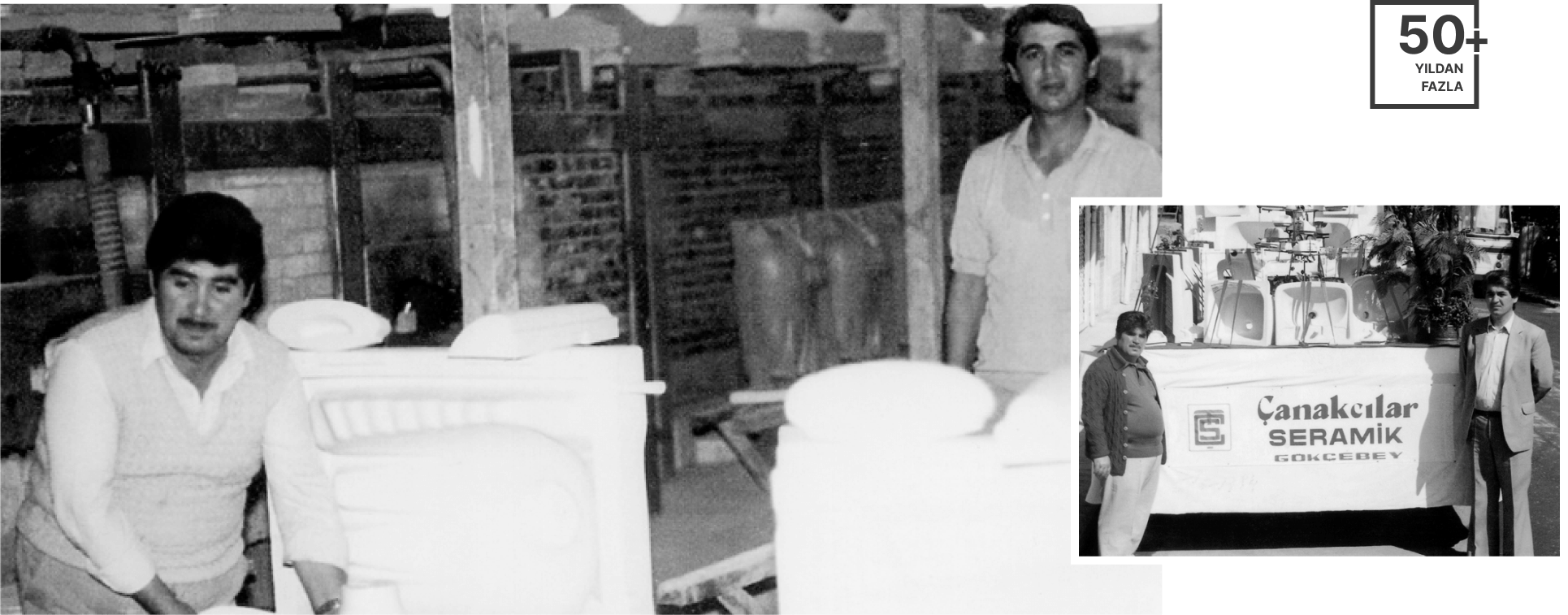

The production and marketing of squat toilets and washbasins began.

-

1975

The production and marketing of dyed stone began.

-

1979

The decision was made to switch from dyed stones to vitrified ceramics, and investment was planned.

-

1981

The production of the first fabricated squat toilets began in Gökçebey.

-

1987

New land for a factory in Çukur Village was purchased. The production and marketing of washbasins in various sizes began.

-

1989

The foundations for a new factory were laid.

-

1991

A new factory was commissioned.

-

1993

A new, domestic, 90-meter tunnel oven was commissioned.

-

1997

A Bricesco oven was purchased and imported.

-

1998

A 50 cubic-meter CDS drying oven was imported from the United Kingdom. A decision was made to invest in the largest tunnel kiln in Turkey, the Balkans, and the Middle East.

-

1999

A 111-meter German Riedhammer tunnel kiln was installed, and production began.

-

2000

Creavit was certified to ISO 9001 Quality Assurance System Certificate, German LGA Norms, and Israeli Standards. Creavit exported its products to 23 countries.

-

2003

Exports, which stood at approximately half of the production capacity, accounted for 45 percent. Creavit exported to more than 30 countries. The bathroom furniture production facility commenced production, and marketing activities began.

-

2004

The first pressure casting (Porvair) system was commissioned for individual sink production.

-

2005

In Çaydeğirmeni, Devrek, the foundation for the Creavit Bathroom and Doxa Office Furniture plants (indoor area of 15,000 m² and outdoor area of 60,000 m², totaling 75,000 m²) was laid.

-

2006

Creavit’s bathroom furniture production commenced in the new furniture factory. The Gökçebey Mithat–Mehmet Çanakçı Vocational School was built.

-

2007

The Gökçebey Mithat–Mehmet Çanakçı Vocational High School commenced education. Office furniture production also began.

-

2008

Creavit’s founders, Mehmet and Mithat Çanakçı, were awarded the “TBBM Order of Merit” by the Speaker of the Grand National Assembly of Turkey for their contributions to society.

-

2009

Creavit was chosen as the most trusted brand in its category and won the “Consumer 2009 Quality Award.”

-

2010

Creavit was certified to ISO 10002 Customer Satisfaction Management System, a first in its industry.

-

2010

The Creavit Concealed Cistern plant was commissioned.

-

2011

The Creavit Toilet Seat Cover manufacturing facility moved from the Gökçebey Central facility to Çaydeğirmeni to complete the modernization process.

-

2012

Sink, washbasin, and bathroom faucet production lines were commissioned at the Çaydeğirmeni plant.

-

2014

The classic casting machines were modernized, and new ones were added.

-

2014

Investments were made in pressure casting machines to facilitate the production of large sinks with shelves. A decision was made to continue our growth trends in the sanitary ware industry and to invest in the second Riedhammer furnace with the same capacity.

-

2014

Investments were made in pressure casting machines.

-

2015

Step 2: The German Riedhammer brick tunnel oven was installed and operated.

-

2015

CREAVIT joined the TURQUALITY program, which offers industrial support to Turkish brands, and agreed to cooperate with International Design Agencies.

-

2015

An investment was made to modernize and expand the indoor area capacity at sanitary ware production plants to 80,000 m². A decision was made to search, source, and install pressure casting systems for toilets, glazing robots, and CNC machines for product development.

-

2016

A modernized pressure casting factory was established, modernized drying ovens were commissioned, and the infrastructure for air conditioning was built.

-

2016

A modernized storage shelf system with an optical reader was established. A cogeneration facility was established, and power generation commenced.

-

2017

Five glazing robots were purchased from the industry’s leading glazing robot manufacturers and commissioned.

-

2018

The information systems’ web infrastructure was renewed.

-

2018

The ERP SAP transformation project was implemented.

-

2019

Factory modernization investments continued, and the foundation for the foundry air conditioning plants was laid.

-

2020

The Creavit Foglia series, designed by Defne Koz, won three international awards.